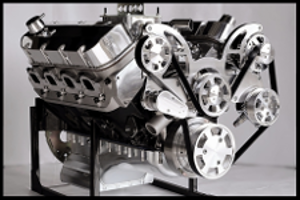

SBC CHEVY FABRICATED TALL ALUMINUM VALVE COVERS NO ACC. HOLES # 6147-POL

Available

$98.50

Product Information

| UPC | 333959613675 |

|---|---|

| Product Type | Shipped Product |

| Shipping Cost | $18.50 |

| Number of reviews | 91 |

|

SBC CHEVY 305 307 350 383 400 TALL ALUMINUM FABRICATED VALVE COVERS. Semi bright polished finish. NO ACC. HOLES. *** IMPORTANT NOTE ***

You may add items into your shopping cart but in order to check out you will have to call us. Our check out feature on our website is being upgraded at this time. We can take your order over the phone and answer any technical questions you may have. We accept all major credit cards, cash, check, and money orders. Just give us a call at 423-722-5152 and we can process your order promptly. In the event you attempt to reach us outside of our operating hours, please leave us a detailed message and we will return your call at our earliest opportunity. These valve covers have a somewhat bright semi polished finish. We find our customers prefer a finish that is somewhere between a high polish and semi polished look. We have sold thousands of these over the years, and all have been satisfied with the finish. These are considered a polished finish, but not to the highest degree such as chrome plating would appear. We can honestly say they have a much better shine than our pictures show them to have. You will notice the strong reflections on the sides in the above pics, yet very little on the top. This is an illusion. The tops are as reflective as the sides are.

These valve covers do not have the accessory holes in them. This is to allow for custom placement.

You will have to remove the internal baffle in the valve covers when using stud girdles.

Part number 6147-POL Notice the high quality welding around the thick plate aluminum rail. Many fabricated valve covers on the market are not like this. The welding is first class. The billet rails on these valve covers is approx. .225" thick. The aluminum sheet metal is approx. .075" thick. We know many on the market to be much thinner in these areas. This is why many other sellers fail to mention these specs.

As you can see in the picture below these valve covers have a thick billet rail. The pic below is a file photo of our simular version with acc. holes. This pic is to show the billet rail. This sale is for the model without acc. holes. You will have to remove the internal baffle in the valve covers when using stud girdles.

OUR MOST POPULAR VALVE COVERS You will receive the valve covers as pictured in the top of the add. The valve covers you will receive will not have the acc. holes in them. These are a top seller at our store. These valve covers are 3.250" tall on the inside not including the valve cover gasket. Most vc gaskets on the market are approx. .175" thick, and this brings the total height to 3.425". There are extra thick gaskets available that will bring the height to approx. 3.650", and will certainly clear most any stud-girdles and roller rockers on the market with ease. Our Gold Series stud girdles have oversized bars that are wider then most and these valve covers do clear them with ease with the use of the regular .175" thick vc gaskets. These valve covers are made from aluminum plate/sheet, not cast aluminum. They have a true billet aluminum rail, not folded over sheet aluminum as many do. There are many similar valve covers on the market, and some are inferior by comparison from what we have seen. *********************************************************** Important Note. We have used these valve covers on thousands of our high performance engines for over 10 years without any issues. On occasion, you may notice a slight degree of warpage on the rails before installation. This is due to the heat generated by the massive amount of welding done around the outer edge of the rails. This warpage is not a problem. When the valve covers are bolted on, they will pull down flat and seal well. Any micro amounts of variation left over after you have bolted them down will be compensated for by the gaskets. Any and all fabricated valve covers with such welding on the rails will have this characteristic. It's simply not a problem in the least. We dyno many of the engines using these valve covers. The engines are brought up to considerably high rpm levels, and rarely do we ever see any signs of oil seepage. They seal very well. The extra thick valve cover gaskets we use do an excellent job of sealing around the valve covers: Part number 7483-ET. See our other listings for these. Every engine we build uses the extra thick gaskets. When we dyno a brand new engine, the crankcase pressure is higher than normal until the engine rings seat. This causes the oil to seep from any possible exit on the engine, such as around the valve covers and gaskets. We had always used our regular black neoprene gaskets on the engines but on occasion had to use the extra thick ones due to stud girdle clearance with certain heads. Our engine builders noticed that the extra thick valve cover gaskets had virtually zero seepage as compared the regular neoprene gaskets. As we see it, the extra thick gaskets are the key factor in eliminating seepage. Extra thick valve cover gaskets also give the engine a more pronounced (wide/tall) appearance.

The finish on these valve covers may on occasion have very minor cosmetic flaws on them. In the world of mass production, it's to be expected. The massive amount of welding on the rails can sometimes leave small spatter marks in some areas. You may also see very minor scratches in the finish. These flaws are only noticeable upon close observation. Once mounted on the engine, these very small cosmetic blemishes are not noticeable from a distance of several feet. In most cases, the valve covers are flawless or nearly flawless. There are some very high end fabricated valve covers on the market that cost four to five times as much, and on those you may even find minor flaws, but it's less likely due to their extreme cost. As mentioned above, you cannot see these minor flaws from the normal viewing distance standing in front of the car. ****************************************************** These valve covers will certainly clear most any stud-girdles and roller rockers on the market. Our Gold Series stud girdles have oversized bars that are wider then most and these valve covers do clear them with ease. You will have to remove the internal baffle in the valve covers when using stud girdles.

The rocker studs used in our engines are the ARP long version as that is what is required for the huge/thick Comp High Energy rockers, and topped off with the over sized stud girdles including the tall poly locks had no clearance issues for these valve covers. We have used over 1500 sets of these or similar style valve covers on our sbc engines, and used as many 5 different popular styles of roller rockers and yet to have an interference issue. This is not to say you will never encounter some interference with certain rockers on the market, but the Comp High Energy rockers, and the huge Scorpion race series have given no problems and they are far from small in size. It would be fair to say that there are few if any roller rockers or stud girdles on the market that will give you a problem with these valve covers. The picture below is one of our engines with the large Comp High Energy rockers and our over sized stud girdles that will be topped off with a set of these style valve covers. Also notice that we have the stud girdles set high up on the on the poly locks and clearance is still not a problem. Our engines all use 200 long valves, with 1.46 diameter springs. This makes valve cover fitment even more challenging. The valve cover gaskets we use are normal thickness, but in some instances you may encounter a fitment issue and the use of thicker valve cover gaskets becomes an instant cure in most cases. AFR heads will require the thicker valve cover gaskets due to the higher than normal spring pocket height. You will have to remove the internal baffle in the valve covers when using stud girdles.

A few more pics below of these valve covers on our engines.

These were taken outdoors in mild to moderate sunshine.

See our other listings for many valve cover accessories.

|

Customer Reviews

-

From ebay user e***a

GOOD SELLER

Reviewed by e***a on July 22, 2021, 10:24 a.m. | Permalink

1 of 1 customer found this useful

-

From ebay user 2***2

Great

Reviewed by 2***2 on July 22, 2021, 3:31 a.m. | Permalink

This review has no votes.

-

From ebay user g***0

nice stuff

Reviewed by g***0 on July 31, 2021, 12:43 a.m. | Permalink

This review has no votes.